Image: Solar3DCross-posted from Climate Progress.

Image: Solar3DCross-posted from Climate Progress.

Solar photovoltaics (PV) is one of the hottest high-tech areas around.

For instance, 3-D technology is all the rage these days. Now, one company thinks it can bring the concept to solar too.

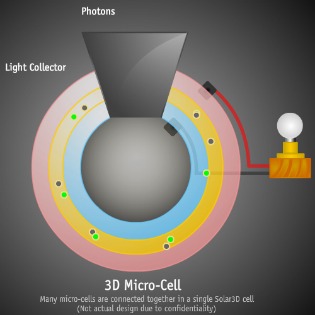

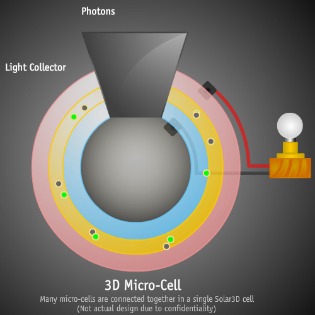

Santa Barbara-based Solar3D is working on a silicon “microcell” at the nano scale that uses an optical element to direct sunlight into a walled-in structure, thus capturing more photons and increasing the amount of electrons that are discharged. If a traditional solar cell is the ceiling of a room, the 3-D solar cell would be the room itself with the optical element acting as a skylight.

Jim Nelson, the CEO of Solar3D, says the cell could theoretically be 25 percent efficient. (A traditional silicon-based cell is usually in the 12-15 percent efficiency range, meaning that 12-15 percent of the sunlight hitting the cell will be turned into electricity. High efficiency cells are now reaching above 19 percent, with record cells hitting over 24 percent in the lab.)

But let’s acknowledge the key word here for the 3-D solar technology: “theoretically.”

Although Solar3D says it is ahead of schedule in development of its cell, it won’t be done with its working prototype until later this year. And it won’t be until 2012 when the company actually plans to ramp up production — assuming its prototype works as expected.

Nelson, who stopped by our office this week to chat with Climate Progress about the company, is a firm believer that next-generation technologies are the key to scaling solar photovoltaics. He doesn’t see the current crop of conventional thin films and silicon-based panels as adequate. And, like the leaders of many early-stage companies, he would shift resources from the government’s project development incentives (grants and loan guarantees) to its competitive research and development programs.

His view is representative of a common debate in renewables generally and solar PV specifically: Which is better — focusing on R&D, manufacturing, or project-level deployment to bring down costs?

“In an ideal world, we’d have an appropriate amount of all three,” says GTM Research Senior Solar Analyst Shyam Mehta. “You need all three for different reasons. Spurring innovation is a combination of focusing on existing technologies and coming up with new ones — but clearly deployment-based incentives give early-stage companies a chance to scale.”

One of the world’s largest solar manufacturers, First Solar, is a great example of this. The company began working on cadmium-telluride thin film modules in 1984. But it wasn’t until the 2000’s, when Germany implemented a feed-in tariff to encourage rapid solar development, that First Solar was able to scale manufacturing to dozens of megawatts of capacity. A couple years ago, the company became the first ever to manufacture a module below $1 per watt and reach over 1,000 megawatts of production capacity.

“First Solar’s success had a lot to do with factors outside the company’s control. Had there not been robust demand for projects in Germany, they wouldn’t have been able to scale up like they did,” says Mehta.

The history of solar has been filled with all kinds of innovative concepts and technologies, many of which have never taken off because of technical problems or unforeseen capital requirements when scaling. We could go down the list of solar inks, paints, plastics, and variations of thin films that have been called “revolutionary,” that are still mostly in the lab, but the list would be very long (see this story on a potentially 90 percent-efficient cell.)

That’s not to say many of these important innovations won’t have a material impact in the future; just that they take much longer to scale than is often thought. And competing with the current crop of silicon-based products — which are still in the process of substantial technical progress — is tough.

Here’s another recent example: Five years ago, a number of companies were claiming that high-efficiency thin film products called CIGS (Copper Indium Gallium Deselinide) would soon dominate solar. At that time, the world was facing a shortage of silicon and technologies that didn’t use silicon were very attractive to investors.

However, major companies that looked promising (Heliovolt, Miasole, Solyndra) had troubles controlling costs and getting their manufacturing processes right. Even with billions of dollars invested in R&D from venture capitalists and a dramatic increase in overall global solar installations, companies still struggled. Why? Because it takes more than just a “revolutionary idea” to bring a technology to market. It takes many years of market experience for a technology to mature.

That’s what’s happening in CIGS today. Learning from earlier troubles, a handful of CIGS producers are starting to crank out product. In fact, a company not in the original high-profile pack of companies, Solar Frontier, just opened a 1 gigawatt capacity plant in Japan. Even with that development, global capacity will be about 3 gigawatts sometime next year — still small compared with the 50 gigawatts of total production capacity. But the CIGS sector is now starting to hit its stride.

But if next-generation thin film technologies are beginning to run, conventional silicon-based PV has been in a full-on sprint: Helped along by lower-cost Chinese producers, those technologies represented more than 85 percent of total global production in 2010. This dominance came about not because governments “picked” silicon PV as the wining technology; it happened because the technology was best fit to meet the rapid deployment goals in countries around the world.

“Conventional PV was there and ready to meet demand,” says GTM Research’s Mehta. “But eventually, there will be a technology that comes in and takes its place. And that may not be as far away as people think.”

Indeed, after years of consistent cost reductions, conventional PV manufacturers are starting to “get stuck” and are finding they have fewer options, says Mehta. By 2015, he says, many of the costs may have been squeezed out of the current suite of conventional silicon-based manufacturing lines.

“Right now, silicon is dominating. But sooner or later, we might be facing more of a revolution than an evolution like we’ve seen.”

That could be good news for companies like Solar3D. If the company has a cell that actually works, it seems to have a decent plan to deploy the technology in an efficient way. Nelson says that the cells are designed to be produced on existing manufacturing lines, and can be dropped into an existing module. That would take away the need to create a whole new set of manufacturing equipment (one of the problems with CIGS) and allow them to substantially increase the efficiency of panels.

“The whole idea is to reduce costs and maximize efficiency within lines we have now,” says Nelso.

Those cells need to get developed first — highlighting the need for a solid focus on research grants, lab partnerships, and competitive prizes for innovative technologies. But as history has proven, they won’t get anywhere without a reason to manufacture — which means continued incentives for deployment are important as well.

That’s why we need a combination of all three types of incentives: funds to encourage more R&D and get the next generation of technologies primed for market; incentives to scale up manufacturing and newly-commercialized technologies a chance to scale; and deployment incentives that provide the most cost-competitive products with a path to market.

“It’s not an either/or,” says Mehta. “They’re all important for different steps of the technology chain.”