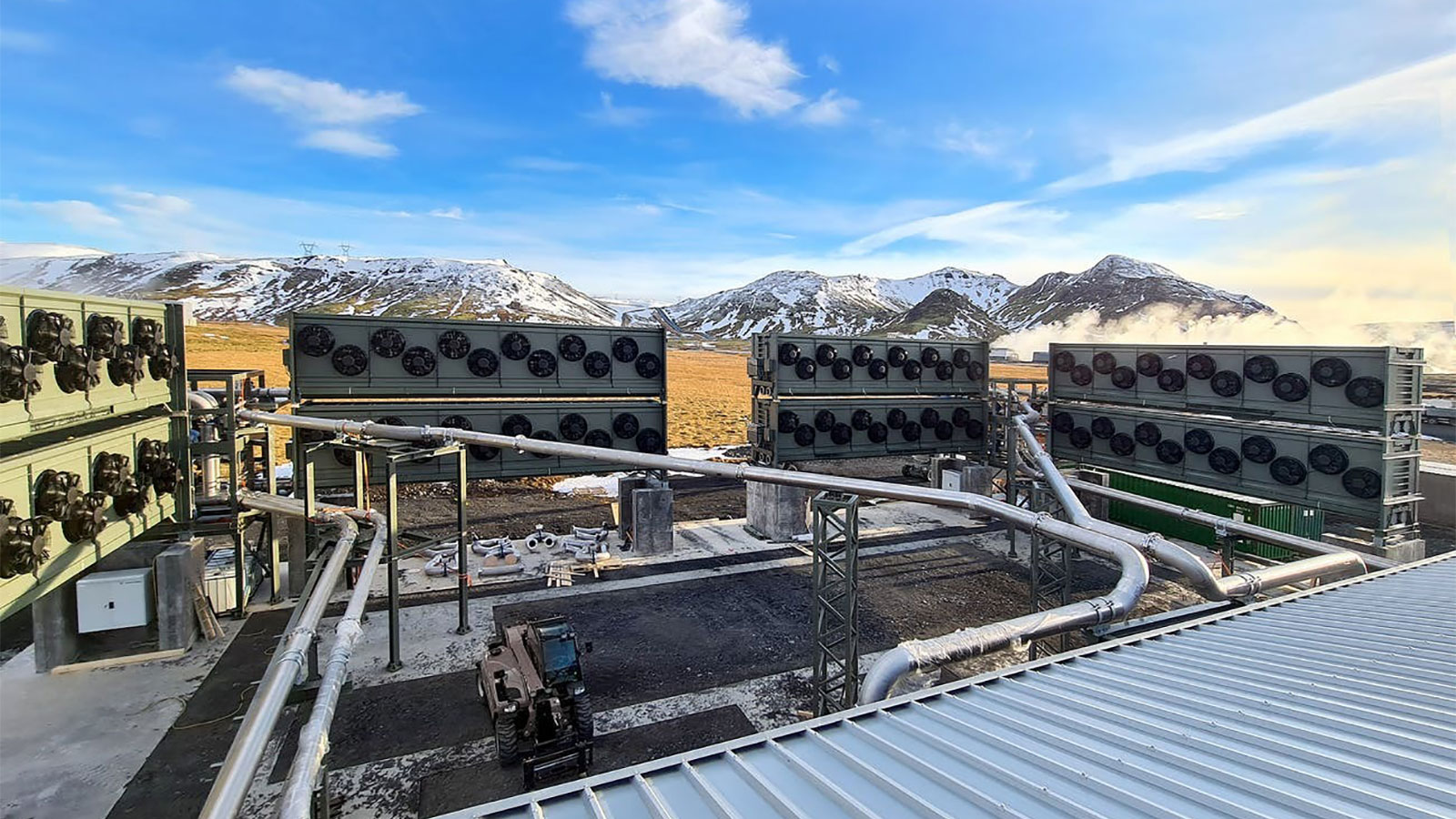

In January 2021, eight shipping container-sized boxes were assembled in Hellisheiði, Iceland, next to the third-largest geothermal power station in the world. Twelve giant fans mounted on the outside of each box will start spinning later this year.

The facility, called Orca, is intended to suck approximately 4,000 tons of carbon dioxide directly from the air each year. Developed by the Swiss engineering firm Climeworks, Orca is the largest example of direct air capture to date — a technology intended to suck carbon dioxide out of thin air.

“To me, this is kind of the last hope,” Christoph Beuttler, the carbon dioxide removal manager of Climeworks tells Grist. “This, together with reducing emissions and planting as many trees as we can, enable[s] us to just make the Paris Agreement.”

You can think about the carbon dioxide in Earth’s atmosphere like a bucket. Today, that bucket is almost full: We have about nine percent of the volume left to fill if we want to stay below 1.5 degrees Celsius of warming by 2050. To keep that bucket from overflowing, we’ll certainly have to cut back on global emissions (which, with the exception of 2020’s pandemic shutdown, are projected to keep rising).

But all of the pathways that keep us at or below 1.5 degrees C, as outlined by the Intergovernmental Panel on Climate Change, also include development of direct air capture technologies like the giant fans set to start spinning in Iceland. Direct air capture can’t keep us below that threshold on its own, but it can help poke a hole in our proverbial carbon bucket to drain out some of our past emissions.

To make a big enough hole, though, this tech will have to remove billions of tons of carbon dioxide from the air each year. Such projects represent “an engineering project probably larger than has ever been created by humanity in the past,” says Jeffrey Reimer, a materials chemist at The University of California Berkeley who is not affiliated with Climeworks. He says there’s still a long way to go, but a few key pieces have fallen into place and set the project in motion.

The regulatory landscape started to shift in 2018 when an adjustment to the U.S. tax code expanded a tax credit called 45Q, which gives businesses tax breaks for capturing carbon dioxide. Businesses can glean the credit by sequestering the gas or by using it to squeeze additional hydrocarbons out of oil — a process called enhanced oil recovery, which might be economically feasible, but also sustains our dependence on oil.

Climeworks will not engage in enhanced oil recovery, Beuttler says.

“The idea is really to provide a non-fossil source of CO2 for fuels, products, and materials, rather than be a means to extract more fossil CO2 from the ground,” he says.

Companies needed to start building air capture facilities within seven years to take advantage of the tax credit. And that has already started to happen. Then in August 2020, the United States Department of Energy announced $13.5 million in funding for direct air capture projects intended to draw carbon dioxide from ambient air (not attached to a power plant). That support was coupled with increasing demand from private companies. More and more large multinationals are paying for carbon dioxide removal to achieve their climate targets and get to net-zero or net-negative emissions by 2030. Climeworks already provides its carbon dioxide removal service to several businesses, including big tech companies.

Direct air capture is not without its challenges, namely high costs and concern that we might shirk necessary policies to curb current emissions in favor of tech that erases past ones. And the net benefit depends on what we do with that carbon dioxide once it’s removed. But the bottom line is that the technology now exists to put a dent in our future atmospheric carbon.

“Direct air capture is real,” Reimer says. “And it works.”

How does direct carbon capture work?

Scientists have been capturing carbon dioxide for decades, especially from highly concentrated sources, like power plants. Direct air capture technology is intended to strip the carbon dioxide out of air anywhere in the world.

One way to think of direct air capture, Beuttler says, is to imagine it like “space-efficient artificial trees.” Trees, after all, are the original carbon-capturing machines. But even if we were to cover Earth’s landmasses with natural trees, we still wouldn’t be able to suck up enough carbon to mitigate climate change in the future, explains Klaus Lackner, director of the Center for Negative Carbon Emissions at the University of Arizona. He is also the creator of his own carbon-capturing technology.

Biological approaches, like planting trees, can offer a start to controlling carbon dioxide. But in the long-term, they may not be able to keep up with human activity. Put simply: “Sixty years from now, you better have another forest the size of all the forests in the world,” Lackner says.

Though planting trees will still be an essential part of the pathway to 1.5 degrees C, direct air capture can play a similar role while using less space. It works like this: Air, sucked in with a fan, is passed through a filter which absorbs the carbon dioxide. (Climeworks uses a solid filter, but liquids also hold promise). Once those filters are full of the gas, the units that house the fans (remember the storage container-sized boxes in Iceland?) are closed. The whole unit is then heated to between 80 and 100 degrees C, which kickstarts a process called desorption, releasing the gas.

From there, the carbon dioxide can be cooled down, combined with water, and pumped deep underground. Through a process of rapid underground mineralization, it is removed safely and permanently from the air. Climeworks has partnered with the Icelandic company Carbfix to accelerate that process at the new Orca plant. Alternatively, the carbon dioxide can be combined with renewable hydrogen gleaned from water to create a hydrocarbon fuel — a possible carbon-neutral alternative to fossil fuels. It can also be used in fizzy drinks or in greenhouses to enhance plant growth.

Naturally, the whole process requires some energy use. “The chemistry [of direct air capture] is very nice. It works very well,” Reimer says. “It just takes a lot of heat to push the carbon dioxide back off again.” As Reimer explains, the laws of thermodynamics tell us that we’ll need to use the same amount of energy to release the carbon dioxide captured as we use to collect it.

Generating energy for direct air capture is a “vexing” problem, Reimer says, but there are ways to mitigate the issue. Orca is built adjacent to a geothermal plant, a ready-made source of renewable energy to heat the carbon dioxide. Climeworks’ 14 other plants get energy solely from renewable sources or from burning waste. About 10 tons of carbon dioxide are emitted for every 100 tons sequestered.

Still, that whole process from capture to storage can be done in a small space, Beuttler says. That’s the factor that could tip the balance in favor of direct air capture in the future. When compared to trees, he says, “We need 400 times less space to remove the same amount of CO2, and that includes the renewable energy we need to create for removal.”

Where do we stand?

Capturing carbon dioxide at the gigaton-scale needed to help restore a healthy balance of CO2 in the atmosphere and at a low enough cost to entice investors will take work. But Beuttler says scale and price issues can be tackled together, as they have been with new low-carbon technologies in the past. “When you look at solar panels in the 1990s, it also looked non-viable,” he says. “Now it’s one of the main renewable energy sources because the price has come down.”

When it comes to direct air capture, the projected long-term cost of the service should stand around $100 per ton of carbon dioxide removed, Reimer says. The other thing working in its favor is the fact that “the IPCC still puts direct air capture as one of their primary tools for mitigating climate change.”

Just ten years ago, direct air capture was still an experiment. But when Orca switches on its cadre of carbon dioxide-sucking fans later this year, it will be twice the size of all of Climeworks’ other plants combined.

“It has moved from lab scale to commercial scale,” Beuttler says of direct air capture. “We are proving it is doable.”

In order to restore Earth, we need to restore a healthy balance of CO₂. Carbon dioxide removal solutions can contribute to this. Climeworks operates multiple direct air capture plants and is currently building the world’s biggest climate-positive direct air capture plant! With Climeworks, everyone can remove their own carbon dioxide emissions from the air and then invite their friends to multiply the impact – for free.